Beauty.strength.

durability.

Thousands of Options at Your Door

Doors

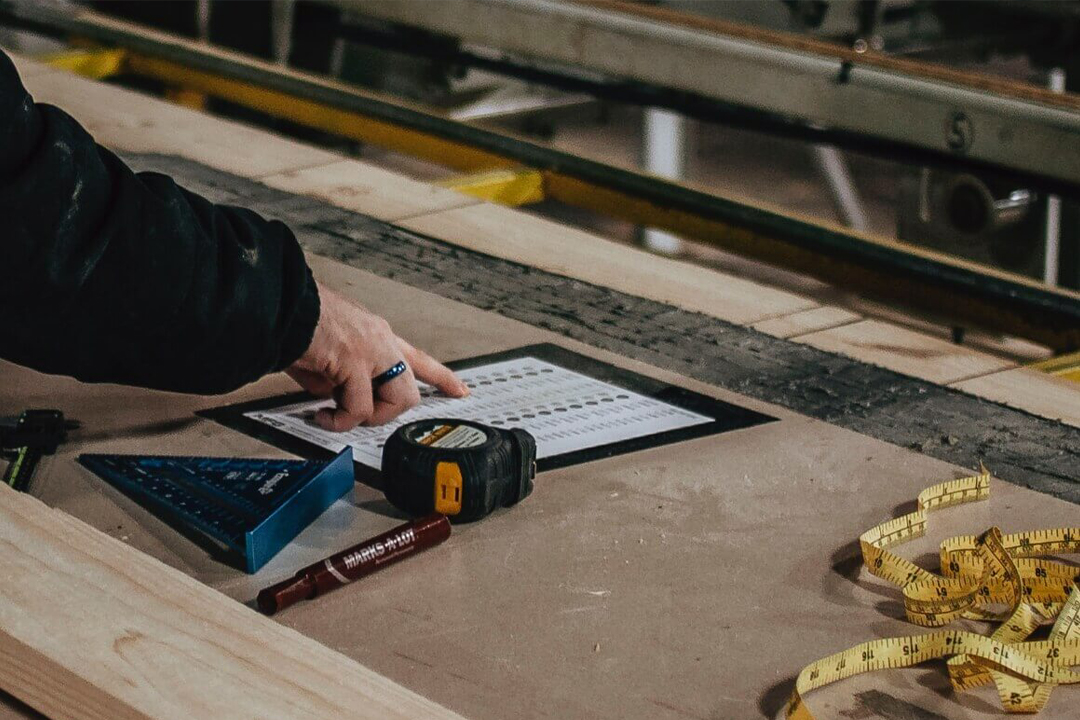

Woodgrain is one of the world’s leading manufacturers and suppliers of hardwood and softwood stile and rail doors, and door components. Distributors, builders, remodelers, architects and homeowners rely on Woodgrain products to build quality homes. Woodgrain is committed to innovation through continuous improvements in manufacturing, investment in design, excellence in craftsmanship and use of the highest quality raw materials to build doors that are as durable as they are beautiful. Woodgrain doors has a rich history of 65 years of quality and craftsmanship. With thousands of combinations between our router carved and stile and rail doors, we make it easy to find your perfect door.

Quality Craftsmanship Meets Superior Performance

Because Woodgrain is a vertically oriented company, we have direct access to the finest wood used for the creation of our doors. Combined with our handcrafted craftsmanship and dedicated quality team, our process and product is simply unrivaled. The proof is in the quality and performance of our doors, but don’t just take our word for it: Woodgrain was voted by builders, developers, and contractors as having the highest quality interior doors in the 2022 Builder Brand Use Study by Zonda. It’s an honor we are very proud of and gives you the confidence that you are choosing the best.

Interior Stile & Rail Doors

Here at Woodgrain, interior stile and rail and Router carved construction doors are our specialty. With thousands of door designs, styles and configurations to choose from, you’ll find the perfect door to complement your individual look. With a number of wood options, we offer a primed interior door options as well which make for a perfect paint grade door.

Interior Router Carved

Woodgrain’s Design Collection MDF Doors are made of medium density fiberboard (MDF) and include both 1 3/8“ and 1 3/4” options available in panel, bifold, and fire rated doors. Design Collection MDF doors offer infinite design options by combining cutting edge technology and old-fashioned craftsmanship. Not simply an MDF door producer, Woodgrain uses its well-honed techniques from decades of wood door manufacturing to build a better door.

Interior Molded & Flush DOors

Backed by years of door expertise and craftsmanship, the Woodgrain Molded Door Collection offers a wide range of designs and sizes to fit your style and space. Woodgrain molded doors are designed to not shrink, swell, split, or crack, so you can rely upon the quality that Woodgrain doors are renowned for when selecting your perfect door.

Exterior Doors

Woodgrain is able to offer a wide array of custom exterior door products that are both on trend and cost-effective. Hundreds of exterior wood door styles are available with 9 wood species to choose from and an additional 24 glass options your guarantee to get exactly what you want. Woodgrain exterior doors are made specifically for you to compliment the look of any home and is sure to increase curb appeal.

Door Finder

With thousands of door designs, styles, and configurations to choose from, you’ll find the perfect door to compliment your style.

About Woodgrain

Woodgrain’s exquisite collection offers a unique combination of beauty and durability. Built upon our superior, quality craftsmanship, we uphold the industry’s highest standard of authentic stile and rail and Router carved construction. With thousands of door designs, styles and configurations to choose from, you’ll find the perfect door to complement your unique style.

Wood Options

With 9 different wood species options, Woodgrain gives you the ability to create the personalized look that you want to transform your space in a subtle or bold way. Woodgrain doors are sustainably made and created with superior craftsmanship, so no matter the option you select, your doors will be durable as they are beautiful.

GLASS OPTIONS

Woodgrain offers 23 glass options to further customize your door. Choose from either a Clear Single Glazed or Insulated Low E glass type. Clear Single Glazed is a single piece of tempered glass, whereas Low E Insulated is coated and insulated, which allows it to reflect radiant heat, making it a more energy efficient option.

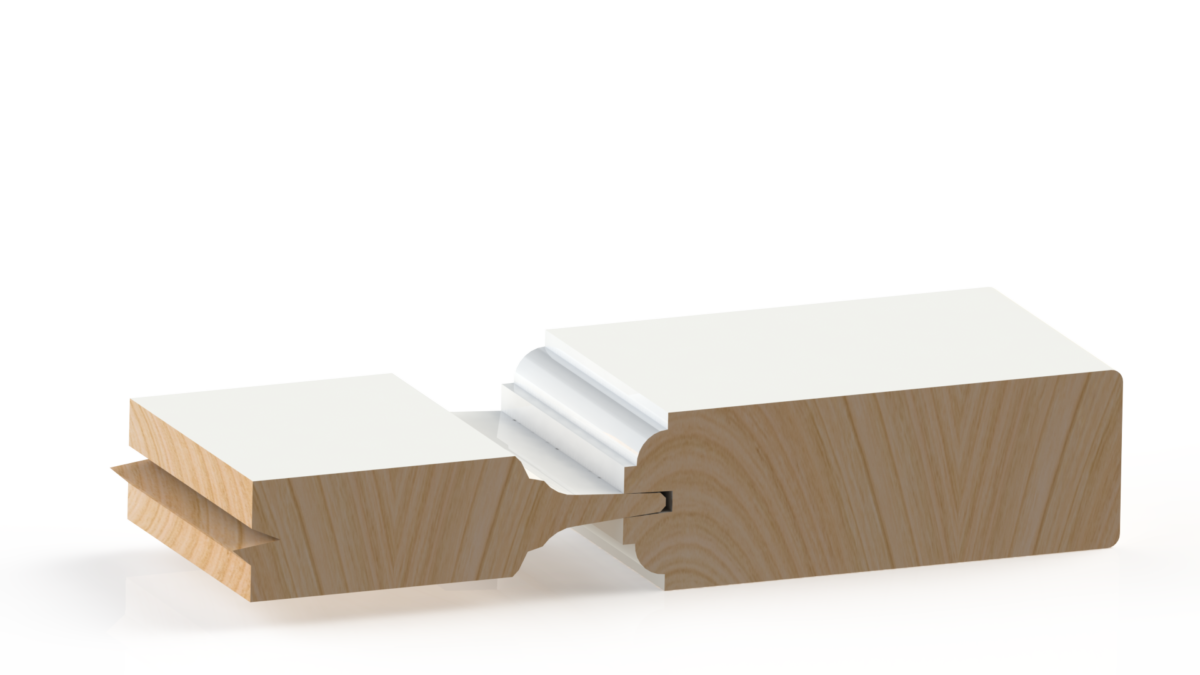

Panel and sticking options

It’s all about details and options, and our doors are available in a variety of sticking patterns and panels. From clean, simple shaker-style flat panel to elegant raised styles, we have numerous panel and sticking combinations so you can find the pattern that fits whatever style you want. Get inspired by seeing all that we have to offer.

Door Resources

View our full line door catalog, door collection sheets, express ship options, technical drawings, warranty information, and our handy how-to guides.

Door Facilities

Nampa

1201 W Karcher Rd

Nampa, ID 83687

Eagan

990 Apollo Rd

Eagan, MN 55121